For more information email tony.strikerhydralink@tutanota.com

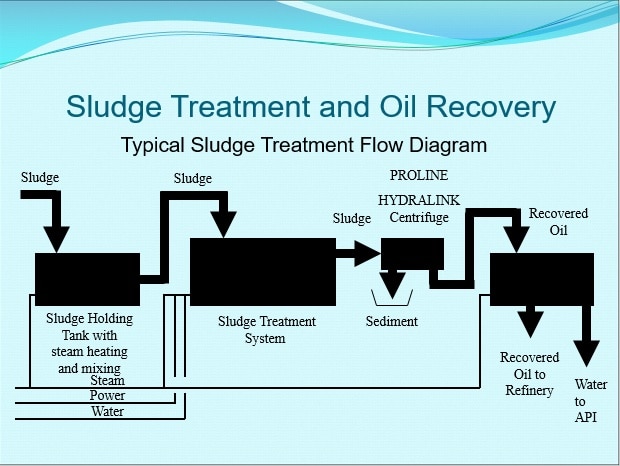

CLEANING OR DE-SLUDGING A CRUDE OIL TANK OR A LAGOON IS ONE THING BUT WHAT DO YOU DO WITH ALL THE SLUDGE? OIL RECOVERY FROM THE SLUDGE IS THE ANSWER

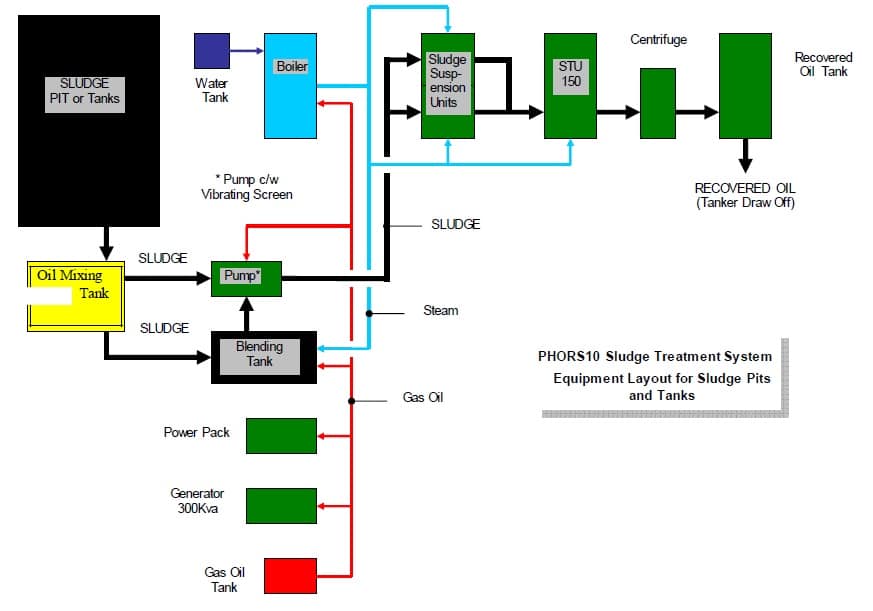

Solution is The PHORS 10 that recovers the good oil from the sludge leaving dry cake sediment and water.

PRO-LINE HYDRALINK TANKSWEEPS OR MANWAY CANNON SYSTEMS

CAN BE USED WITH THE PHORS 10 OIL RECOVERY SYSTEM

Processing rate varies according to the incoming quality and desired outgoing quality but as a general rule 10m3 (13 cubic yards per hour) is a normal throughput giving good quality results

Recovered oil will contain 2% or less BS&W and the Sediment or solids remaining after processing will have 100ppm or less of leach-able hydrocarbons.

The PROLINE HYDRALINK PHORS 10 portable sludge treatment unit is specially designed and fabricated system, of heavy duty, welded construction built around a 40′ ISO hi-cube container box size. The unit is fitted with standard twist locks and carries CSC plating for easy transportation. The centrifuge unit is supplied with its own purpose built support frame for safe operation and maintenance.

All electric motors and the system control panel are rated EExd for Zone 1 refinery use.

The PHORS 10 unit includes:

- Heated pre-treatment system with heavy-duty, electric drive agitator for effective re-circulation and re-suspension of solids in the sludge. Pre-treatment tank has a large external level indicator and high/low-level alarms.

- Electric drive agitator for effective re-circulation and re-suspension of solids in the sludge. Pre-treatment tank has large external level indicator and high/low-level alarms

- Heavy-duty, variable speed electric drive Centrifuge Feed Pumps. Main pump plus standby pump hard piped and wired into the control system for continuous working.

- Chemical Dosing System for improved performance and treatment of a wide range of waste oil sludge materials. The system includes twin half-meter mixing and holding tanks with electric drive agitators and variable speed dosing pump.

- Purpose-built, heavy-duty two-phase Centrifuge to remove solids from the pre-treated sludge and reclaim good quality oil suitable for pumping directly back to refinery storage facilities.

- Centrifuge system includes comprehensive control and alarm systems wired into the system Control Panel

- Centrifuge supplied complete with sediment and recovered oil chutes.

- Purpose-built centrifuge support frame designed for fast and simple site erection and which allows safe access around centrifuge for routine maintenance.

- Electrically driven VISCOTHERM Power Pack for centrifuge drive and control. Unit wired in to centrifuge control panel for safe and simple operation.

- Recovered Oil Holding Tank (3.5m3) with large external level indicator and high/low-level alarms.

- Heavy-duty, variable speed electric drive Sludge Feed Pump for sludge feed to PHORS 10 Unit

- Heavy-duty, variable speed electric drive Recovered Oil Pump to transfer reclaimed oil into adjacent storage tanks or directly back into the refinery system

- All equipment is wired into the main Control Panel for safe and simple operation. All feed pumps stop/start wired into integrated high/low-level alarms.

- System designed for on-site operation in remote locations and has all maintenance items easily accessible.

- Dimensions and Weights:

13.411m long x 2.438m wide x 2.895m high

Weight: Dry: 13,000 Kg

Operating: 33,000 Kg

Utilities Required:

Steam: 4,500 Kg/Hour at 10 bar max

Electricity: 415 V 3 phase 300 KVA

Water: Typical fire hydrant supply for chemical dosing system and wash down

Typical crude oil sludge processing rate 10-25³/hour depending on sludge quality

Recovered oil will contain 2% or less BS&W and the Sediment or solids remaining after processing will have 100ppm or less of leachable hydrocarbons

So Tank cleaning Systems that work safely, efficiently and are engineered to last